Key Features

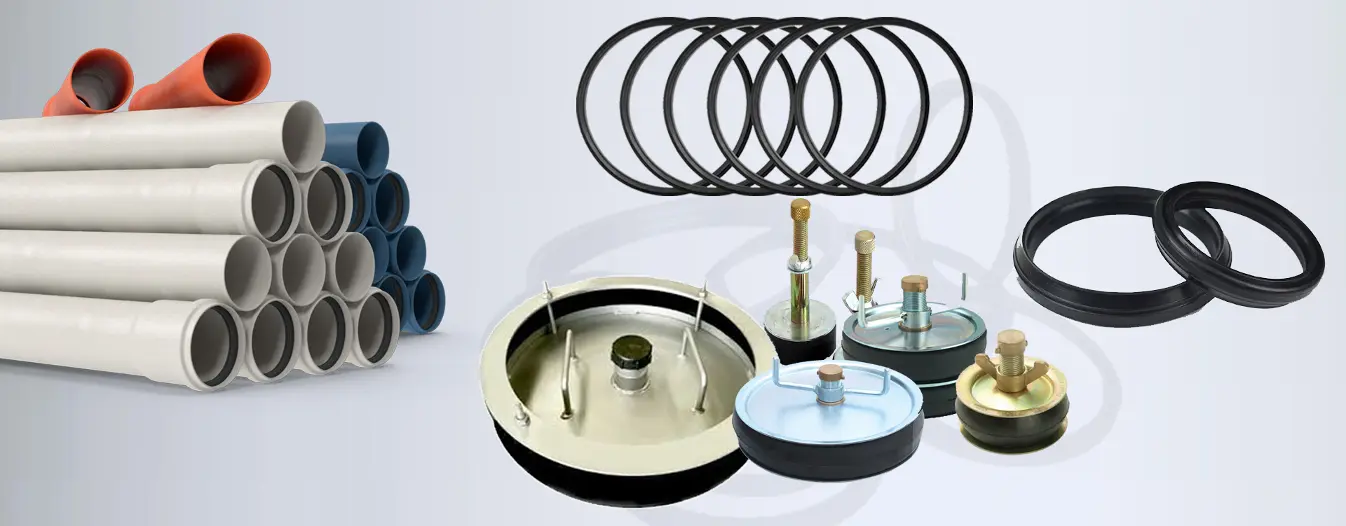

- Enhanced Versatility: Covering a wide range of pipe sizes from 12mm to 40mm internal diameter, ensuring a precise and secure fit for diverse piping requirements.

- Versatile Applications: Ideal for conducting pressure tests across various industries such as telecommunications, refrigeration, air conditioning, heating, processing plants, and food production, showcasing its adaptability and reliability.

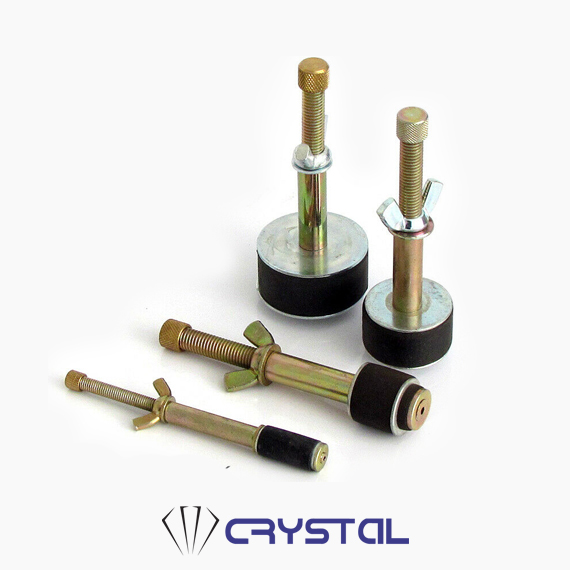

- Engineered for Tough Conditions: Each plug is meticulously crafted to endure pressures of up to 6 bar, making it a robust and dependable tool for rigorous pressure testing tasks.

- Rugged Durability: With zinc-plated steel components offering exceptional corrosion resistance, these plugs have undergone rigorous 90-hour salt spray tests, ensuring long-lasting performance even in harsh environments.

- Uncompromising Quality: Backed by the renowned CRYSTAL brand, these test plugs exemplify the highest standards of quality and reliability in the industry.

Sizes & Dimensions

| Pipe Size Internal Nominal Diameter | Will Fit Pipes With Internal Diameter | Minimum Insertion into Pipe | Overall length | Diameter of waterway | Maximum allowable back pressure | Approx. Weight |

| 12mm / 0.5" | 12mm-16mm | 66mm | 110mm | 4mm | 50psi | 40gm |

| 19mm / 0.75" | 19mm-26mm | 66mm | 110mm | 6mm | 50psi | 50gm |

| 25mm / 1" | 25mm-33mm | 66mm | 110mm | 6mm | 50psi | 70gm |

| 32mm / 1.25" | 31mm-39mm | 66mm | 110mm | 6mm | 50psi | 90gm |

| 40mm / 1.5" | 38mm-48mm | 66mm | 110mm | 6mm | 30psi | 130gm |

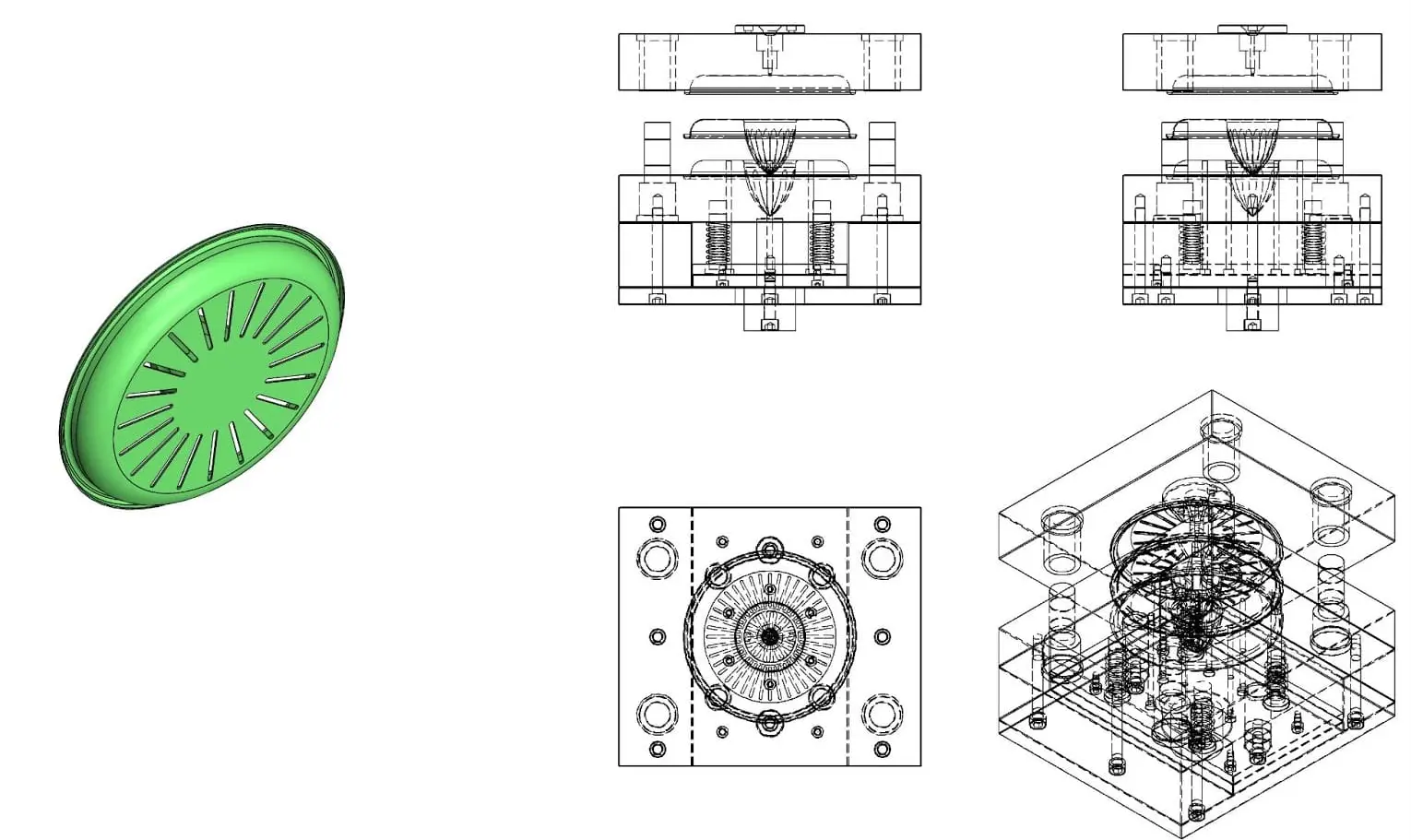

Method of use

- Ensure the correct size of plug is selected to perfectly fit the internal diameter of the pipe.

- Thoroughly clean the installation point to remove any traces of grease or foreign material.

- Precisely insert the plug square to the pipe wall for a secure fit.

- Gradually tighten the peripheral nuts in a diametrically opposite order, ensuring equal tightness. Avoid over-tightening to prevent distortion of the clamp ring.

- Double-check the sealing cap to ensure a tight seal. If the plug has a second outlet, make sure it is also securely sealed.

- Remember, for your safety, always support these plugs with an engineered brace to withstand the calculated back pressure. Never use them without proper support.

For Inquiry and more information

Kindly complete the form, and our team will promptly contact you within 24 hours to offer professional assistance.