Colored Rubber Parts

Enhance Safety, Verify Assembly, and Reinforce Your Brand with Distinctive Colored Rubber Parts

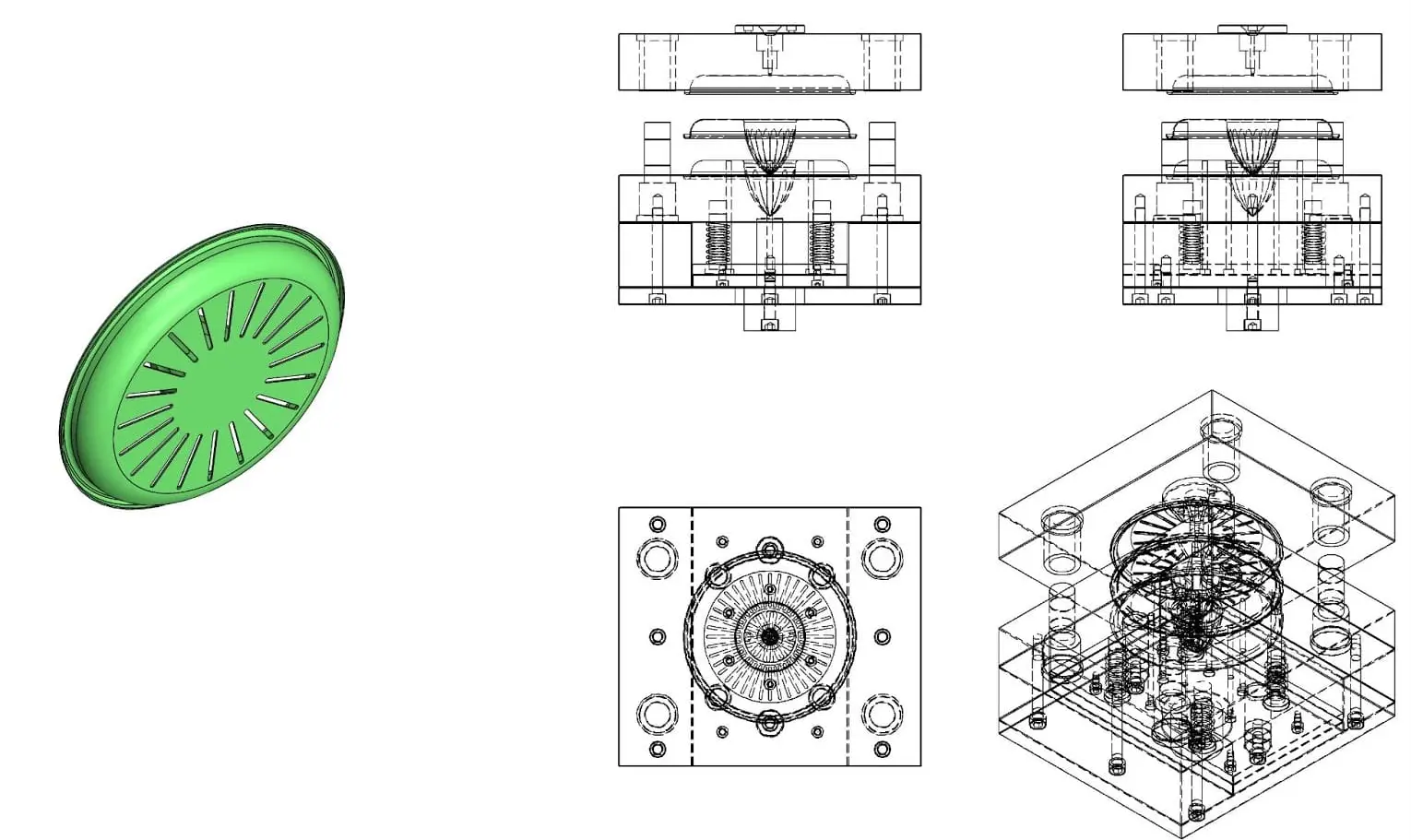

Custom Colored Rubber Parts

Write one or two paragraphs describing your product or services. To be successful your content needs to be useful to your readers.

Start with the customer – find out what they want and give it to them.

What are the benefits of custom-colored rubber parts?

Custom-colored rubber parts offer several advantages across various industries. Whether you're in automotive, medical, electronics, or consumer goods, the color of your rubber components can make a significant difference. Here are four great reasons to consider colored rubber parts for your project:

Distinguish Similar Parts

Using different colors for small components in assemblies helps to quickly distinguish similar parts, reducing errors and saving time.

Reinforce Brand Identity

Strategically using color can boost your brand's recognition. Custom-colored rubber can enhance your components and reinforce your brand's identity.

Improve Safety

Using high-visibility rubber components can boost safety by highlighting key areas and reducing mishandling risks, especially in sectors like construction and manufacturing.

State-of-the-Art Facility for Color Precision

Crystal Rubber Factory prioritizes color accuracy in rubber manufacturing. Our clean facility and state-of-the-art equipment allow us to produce vibrant rubber parts in colors like yellow, pink, and blue to meet your specifications.

Our facility uses high-quality T8 fluorescent lights and LED inspection lights to ensure precise color accuracy. This advanced lighting system helps our trained employees evaluate and confirm the exact color shade of each part to meet your specifications.

Frequently Asked Questions

We can create a wide range of colors, from standard black and gray to more vibrant options like yellow, pink, baby blue, and custom shades. If you have a specific color in mind, we can work with you to match it exactly.

Custom-colored rubber parts are used across various industries, including automotive, electronics, healthcare, construction, and consumer products. Whether for safety, brand identity, or assembly verification, colored parts serve diverse functional and aesthetic purposes.

We use advanced lighting systems, including high-power T8 fluorescent and LED inspection lights, to accurately verify color consistency. Our trained staff conducts thorough inspections to ensure that the color of every part matches your exact specifications.

Yes, using brightly colored rubber components can enhance visibility and improve safety by drawing attention to critical or hazardous areas, helping to prevent mishandling or accidents in assembly lines or operational environments.

We offer a variety of rubber materials for our colored parts, including silicone, EPDM, neoprene, and natural rubber. Each material is selected based on your product's specific performance requirements, such as durability, flexibility, and heat resistance.

Production timelines vary depending on the complexity of the part and the color customization required. However, we work closely with our clients to ensure that we meet deadlines and deliver the highest quality product on time. Feel free to contact us for a more accurate estimate based on your project’s details.

From Design to Delivery

At Crystal Rubber Factory, we’re proud of our customer-driven approach, offering responsive service from design to delivery. Our mission, “Responsiveness - From Design to Delivery,” has helped us maintain a 98% customer retention rate. Contact us today to discuss your specific requirements, and let us help you find the perfect custom-colored rubber solution for your project.