APPLICATIONS

Specially designed for pressure testing and inspection of long-radius elbows in industrial pipeline systems:

🔹 Fabrication and maintenance of elbows in oil, gas, and power sectors.

🔹 Pressure testing of elbow spools before installation.

🔹 EPC and pipeline workshops for fast quality verification.

🔹 On-site testing for elbow joints and welded connections.

Where elbows bend, ELBOW-MAX™ holds pressure.

KEY FEATURES & BENEFITS

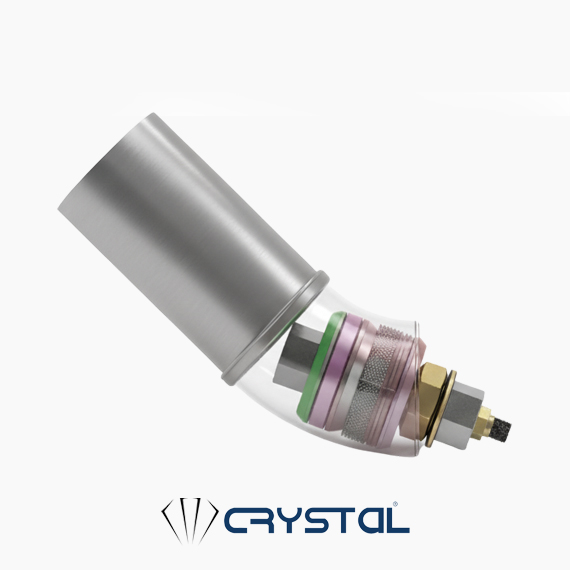

🔹 Engineered for long-radius elbows provides a secure seal without welding or end caps.

🔹 Dual-grip design distributes pressure evenly, protecting the pipe’s internal surface.

🔹 Compact and durable body built for harsh industrial conditions.

🔹 Fast setup for hydrostatic or pneumatic testing in workshops or on-site.

🔹 Compatible with multiple materials, including carbon steel, stainless steel, FRP, and GRE.

🔹 Saves time and reduces testing cost compared to conventional welded caps.

Result: clean, accurate, and efficient testing for every elbow under pressure.

SPECIFICATIONS

|

Parameter |

Specification |

|

Size Range |

3/8″ – 48″ (DN10 – DN1200) |

|

Pressure Range |

Up to 3048 PsiG (234 BarG) |

|

Temperature Range |

−26 °C to +230 °C (−15 °F to +440 °F) |

|

Body Material |

Carbon Steel / Stainless Steel |

|

Seal Materials |

PU/NR/FKM |

|

Surface Finish |

Zinc-Plated, Polished, or Custom-Coated |

|

Connection Port |

¼″ NPT or Custom Options |

|

Customization |

Sizes and materials available upon request |

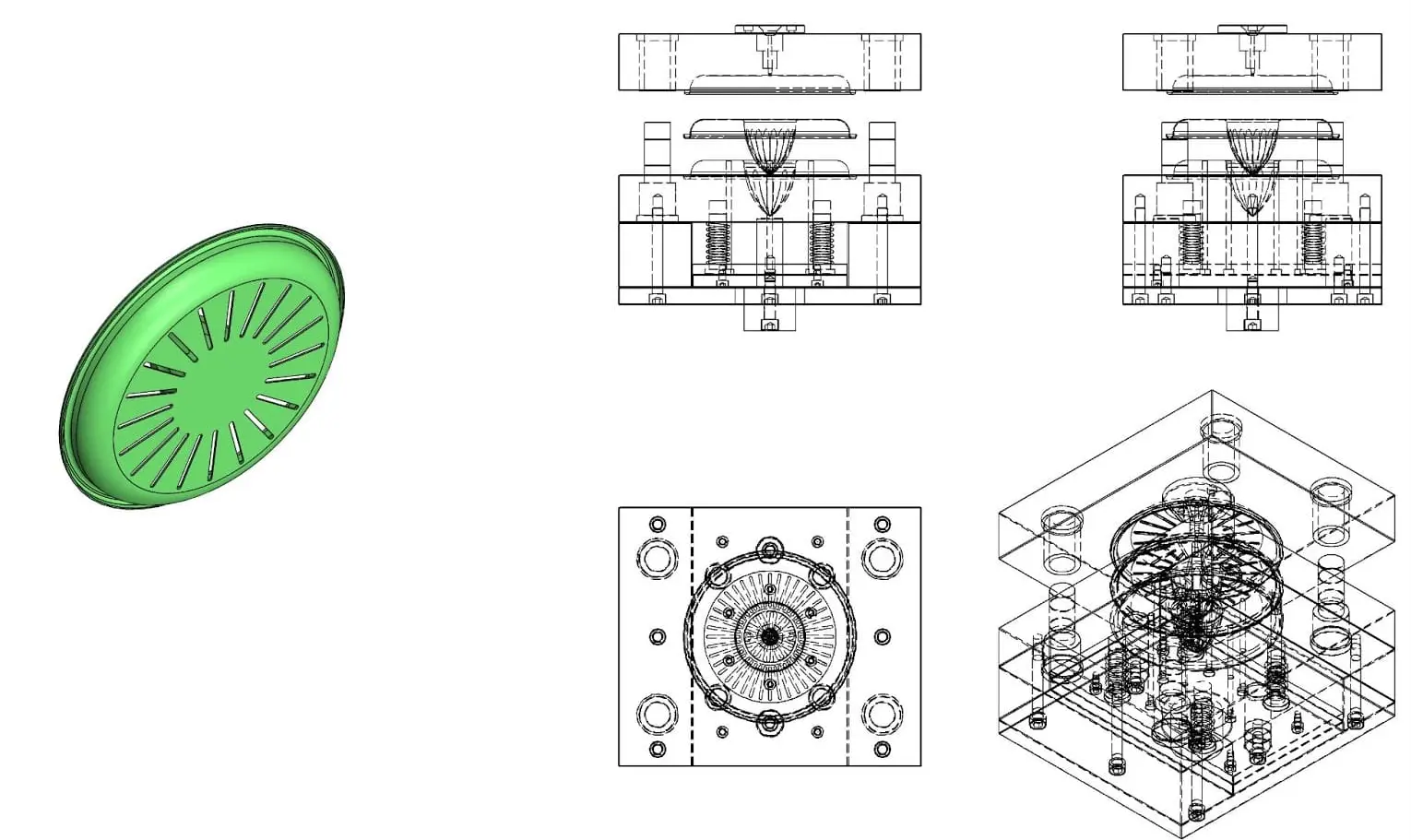

HOW IT WORKS

The ELBOW-MAX™ plug creates a controlled seal inside long-radius elbows to enable safe hydrostatic or pneumatic testing.

- Insert the plug into one end of the elbow.

- Tighten the locking mechanism until the seals are fully engaged.

- Connect the pressure hose to the central port.

- Fill, vent, and pressurize to the required level.

- Maintain pressure for the test duration, then release and remove the plug.

Simple, accurate, and orientation-free, perfect for elbows of any direction or radius.