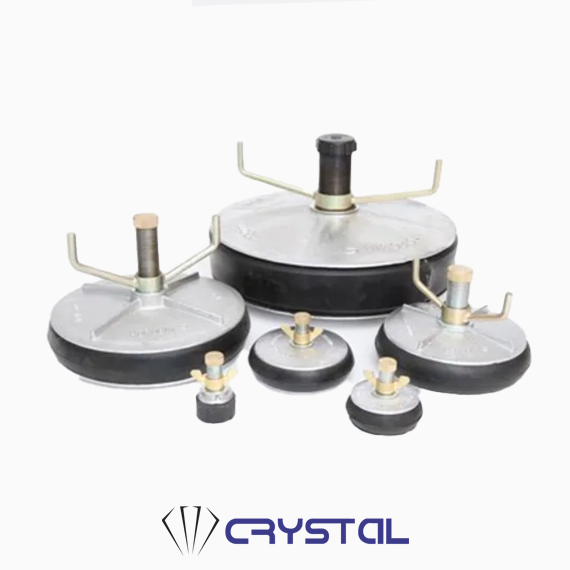

Key Features

- Aluminum plates combine strength with lightness.

- Chemical-resistant seals can be supplied to order.

- “Double Seal” plugs can be supplied to order.

- Steel components are zinc plated to a 90-hour salt spray test.

- Carries the CRYSTAL name – quality guaranteed.

- Nominal pipe sizes, minimum and maximum pipe diameters each plug will fit, maximum test pressure, and weight of plug are below

Sizes & Dimensions

| Pipe Size Internal Nominal Diameter | Will Fit Pipes With Internal Diameter | Overall length | Diameter of waterway | Maximum allowable back pressure | Approx. Weight |

| 40mm / 1 1/2" | 38mm-50mm | 94mm | 1/2" | 30 p.s.i. | 0.17kg |

| 50mm / 2" | 49mm-62mm | 90mm | 1/2" | 30 p.s.i. | 0.22kg |

| 65mm / 2 1/2" | 62mm-77mm | 92mm | 1/2" | 30 p.s.i. | 0.27kg |

| 75mm / 3" | 73mm-89mm | 94mm | 1/2" | 20 p.s.i. | 0.31kg |

| 90mm / 3 1/2" | 84mm-103mm | 96mm | 1/2" | 15 p.s.i | 0.36kg |

| 100mm / 4" | 94mm-110mm | 94mm | 1/2" | 10 p.s.i | 0.36kg |

| 114mm / 4 1/2" | 112mm-130mm | 140mm | 1/2" | 10 p.s.i | 0.47kg |

| 125mm / 5" | 125mm-142mm | 95mm | 1/2" | 10 p.s.i | 0.79kg |

| 150mm / 6" | 146mm-168mm | 96mm | 1/2" | 10 p.s.i | 0.70kg |

| 175mm / 7" | 175mm-200mm | 100mm | 1" | 7 p.s.i | 1.92kg |

| 200mm / 8" | 193mm-220mm | 100mm | 1" | 7 p.s.i | 1.59kg |

| 225mm / 9" | 220mm-240mm | 170mm | 1" | 7 p.s.i | 2.06kg |

| 250mm / 10" | 245mm-270mm | 178mm | 1" | 7 p.s.i | 2.52kg |

| 275mm / 11" | 274mm-328mm | 200mm | 1" | 7 p.s.i | 3.45kg |

| 300mm / 12" | 295mm-325mm | 200mm | 1" | 7 p.s.i | 3.42kg |

| 325mm / 13" | 325mm-360mm | 230mm | 1" | 5 p.s.i | 4.75kg |

| 350mm / 14" | 350mm-385mm | 215mm | 1" | 5 p.s.i | 6.95kg |

| 375mm / 15" | 370mm-410mm | 225mm | 1" | 5 p.s.i | 5.35kg |

| 400mm / 16" | 390mm-435mm | 225mm | 1" | 5 p.s.i | 5.9kg |

| 450mm / 18" | 445mm-495mm | 225mm | 2" | 5 p.s.i | 8.75kg |

| 500mm / 20" | 495mm-550mm | 255mm | 2" | 5 p.s.i | 11.3kg |

| 525mm / 21" | 495mm-550mm | 255mm | 2" | 3 p.s.i | 11.3kg |

| 600mm / 24" | 595mm-650mm | 255mm | 2" | 3 p.s.i | 15.85kg |

Method of use

- Ensure the correct size of plug is selected to perfectly fit the internal diameter of the pipe.

- Thoroughly clean the installation point to remove any traces of grease or foreign material.

- Precisely insert the plug square to the pipe wall for a secure fit.

- Gradually tighten the peripheral nuts in a diametrically opposite order, ensuring equal tightness. Avoid over-tightening to prevent distortion of the clamp ring.

- Double-check the sealing cap to ensure a tight seal. If the plug has a second outlet, make sure it is also securely sealed.

- Remember, for your safety, always support these plugs with an engineered brace to withstand the calculated back pressure. Never use them without proper support.

Inquiry and more information

Kindly complete the form, and our team will promptly contact you within 24 hours to offer professional assistance.